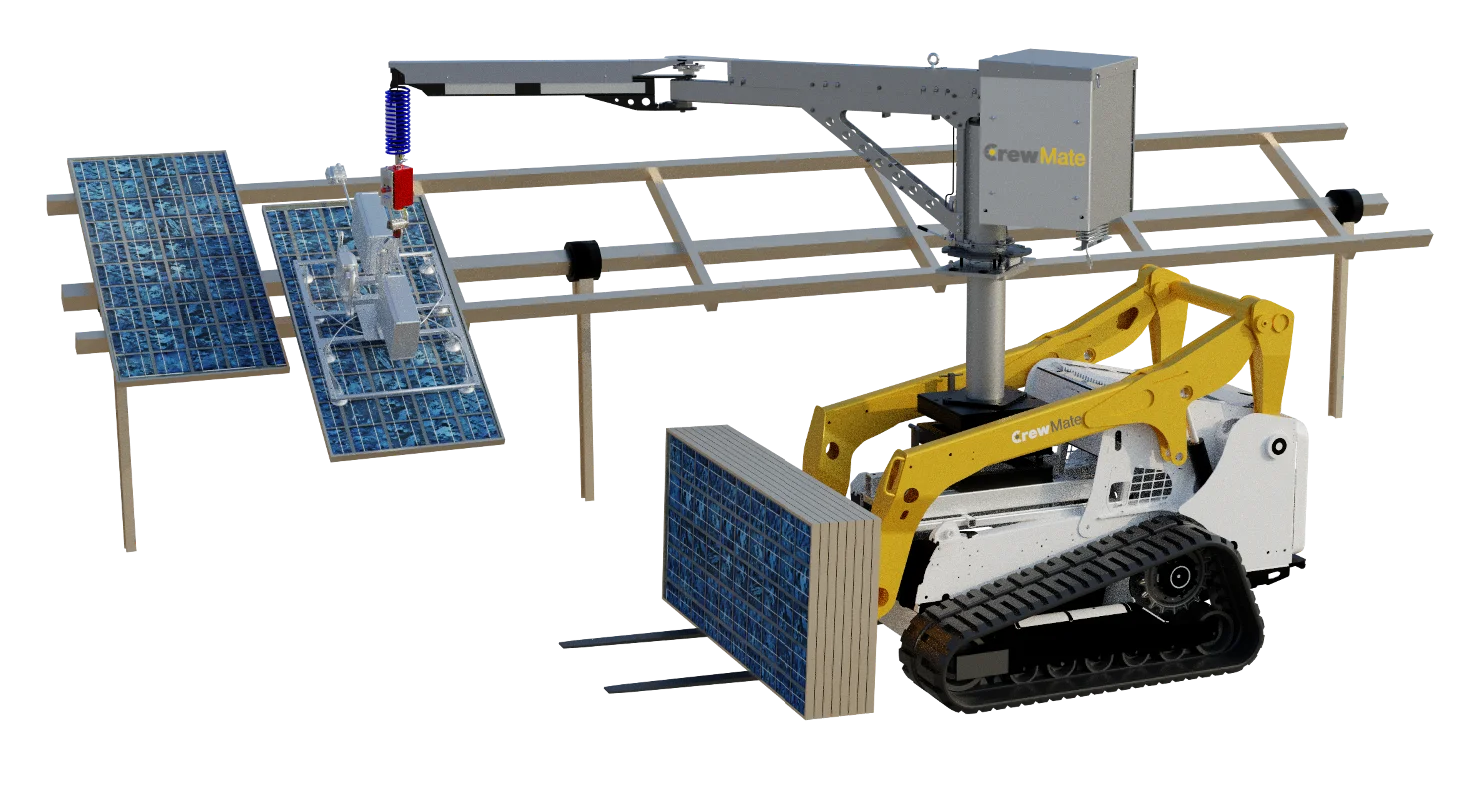

Solar panel lift assist system

Use machine automation to enhance your crew and your business. Increase productivity, keep costs down and create predictability in your solar panel installation process.

CrewMate is now commercially available!

Seamlessly integrates into your existing process

- No additional machines or operators required.

- Team is ready to install panels in just minutes following training.

- Reduces variability in your installation process.

Training as simple

as it gets

- Safety overview and training.

- Gripper and machine operation.

- Start and install panels.

Maximum Usage Across all Solar Field Installations

- Flat and angled mounting.

- Panel install heights up to 9ft and over.

- Single and double panel installation.

- Adjusts to any panel size and weight.

- Any panel orientation and racking system.

Optimize your solar project

Increase productivity

Install panels 2X faster

Improve your schedule

Deliver consistently and streamline your workflow by minimizing variations in your process.

Cost Reductions

Less panel breakage

Less workers comp

Put your best labor to work

in the right places

Benefits your company and employees will appreciate

Lowering injury rate

With less steps and better ergonomics.

Safer operations

Workers maintain control over the CrewMate system.

Additional sensors added to prevent accidents.

Reduce fatigue

Take fewer steps and decrease the total amount of lifting required.

A flexible tool ready to help you get the job done.

CrewMate is ready to get to work on day 1 with no changes to your process or workflow.

Within an hour of introducing CrewMate to your team, you will be operational and installing panels with ease.

CrewMate can be qualified to work with almost any torque tube or mounting configuration.

CrewMate adds predictability, consistency and reliability to your existing process.

CrewMate is an all-in-one tool that keeps your cost low.

- No extra machinery to rent or buy.

- No additional or specialized operators required.

“We are looking forward to partnering with your crews to deploy the innovative CrewMate machine technology. This collaboration aims to significantly increase overall productivity by reducing the costs of solar panel installation by up to 20%. The CrewMate machine is designed with scalability in mind, ensuring that it can be effectively utilized across projects of varying sizes and complexities. This adaptability is crucial for meeting the diverse needs of solar installations, from small-scale DG/ Community solar projects to large-scale utility scale solar farms.”

— Dave Grabau, Director of Automated Machinery

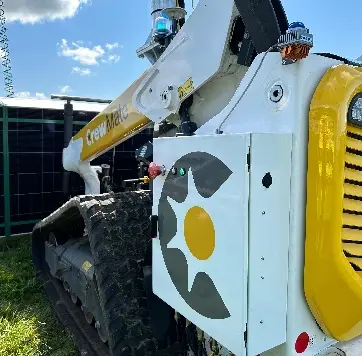

Safety is in our DNA

- Safety is paramount to all of our operations and CrewMate comes prepared to interact safely with your team.

- LiDAR and Radar technology are used to detect nearby objects while the machine is in operation. CrewMate automatically stops and alerts you if an obstacle is detected.

- Remote and mounted remote e-stops give an additional layer of safety.

- Lights and sounds are emitted to alert operator of potantial warnings or operation changes.

Hassle Free Tool

- Won’t damage panels.

- Designed for maximum site/panel flexibility.

- Simple teach functions to learn panel size and racking style.

- Ruggedized for field usage.

Safety First

- LiDAR and Radar sensors are used to detect unwanted presence.

- Alarms and lights to alert operators.

- Reduces fatigue from repetitive motions including lifting and bending. Buoyant panels can be lifted with ease.

Simply Automated

- Learn to operate in under 10 minutes and start installing panels.

- No Complicated Technology or AI to learn or worry about.

- Smart enough to operate in rough terrain.

Uncomplicated Adaptability

- Work with torque tubes up to 9ft and taller.

- Panel weights up to 100lbs.

- Any panel dimensions.

- Operated on slopes and rough terrain.

- Any racking system and panel orientation – flat or tilted.