An integrated solution allowing a quicker journey to market, streamlined production, and simplified service.

Full electric motion system architecture

Scalable. Modular. Configurable.

Adaptive Electrification Management System

Electric Cylinder

Traction Drive Assembly

Drive Train Motor

Software

Adaptive Electrification Management System

Adaptive Electrification Management System

Advantages

Patented common high voltage busbar & coolant modules to reduce cable connections and component count, and increase reliability and efficiency

Bookcase architecture to minimize integration time, costly downtime and cost of repair

Designed to meet the highest global standards and regulations

Electric Control Module

Electric Control Module

Advantages

Allows component configuration and machine differentiation

Versability and ability to handle a wide range of input and output generation

On board charging and dynamic brake control

High voltage battery input

High Voltage Distribution Module

High Voltage Distribution Module

Advantages

Common DC Bus Interface to connect all the system modules without needing cables and connectors

High voltage distribution for DC power

Integrated branch fuses protection

DCDC Converter Module

DCDC Converter Module

Advantages

Common DC Bus intergace to reduce the number of electrical cables and connectors

Common liquid coolant connection to reduce number of liquid cooling lines while increasing component life

Supports status monitoring and output voltage control via fieldbus

Single Axis Inverter Module

Single Axis Inverter Module

Advantages

Common liquid coolant connection to increase component life while reducing number of cooling lines

Combined motor brake and motor feedback interface to reduce the number of electrical cables, connectors and electric modules

Pluggable connections to optimize integration and ease of use

Low voltage Interface

Dual Axis Inverter Module

Dual Axis Inverter Module

Advantages

Dual axes to provide power to two lower control aces for a compact solution

Common liquid coolant connection to reduce number of liquid cooling lines while increasing component life

Combined motor brake and motor feedback to reduce the number of electrical cables, connectors and electric modules and Brake Bypass functionality to support the use of a dynamic brake to remove energy from the system

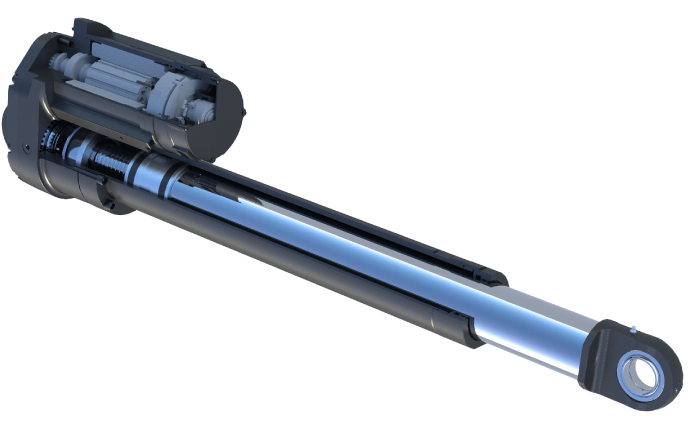

Spherical Rod End

Motor

Power and signal connectors

Gearbox

Ball screw

Nut

Rod

Electrical Cylinder

Electric Cylinder

Powerful, easily configurable, and efficient electric motion hardware

Our Electric Linear Cylinders, also known as Electro-Mechanical Actuators (EMA), are the workhorse hardware required for powerful yet efficient actuation for all-electric construction systems. Our product is trusted for its long-lasting performance and configurable options to help you optimize your machine. Our in-house design and manufacturing capabilities make it easy to integrate this robust technology with power electronics and controls to help you build your differentiation into your machine.

Advantages

High force performance with peak forces well over 130kN, specifically designed and manufactured to meet the current performance demands (force/Speed) of hydraulic cylinders for lift, tilt, boom, and stick

Trusted by OEM’s worldwide as the performance leader you can count on to meet performance specs

Proven hardware that is ready for quick integration, test and validation, and production

Motor

Internal Brake

Gearbox

3 Phase Power Connectors

Coolant Ports

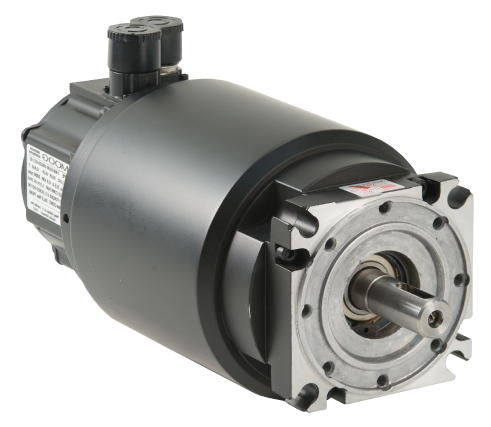

Traction Drive Assembly

Traction Drive Assembly

Moog has sophisticated motor design and manufacturing capabilities that ensure rugged performance and flexibility integrating into your overall system. It is compact, lightweight, and efficient with the impressive power density and optimized package size. With designs for traction and power train applications, high torque and load capacity, and special lifetime seals.

Advantages

Interconnect hardware product easy to integrate into the electrification system reduces development, validation, and verification time

Speed and torque profile to match and replace existing hydraulic traction motors

Tunable to give you the right acceleration and deceleration profiles to match your operations

Stator

Rotor Shaft

3 Phase Power Connection

Coolant Ports

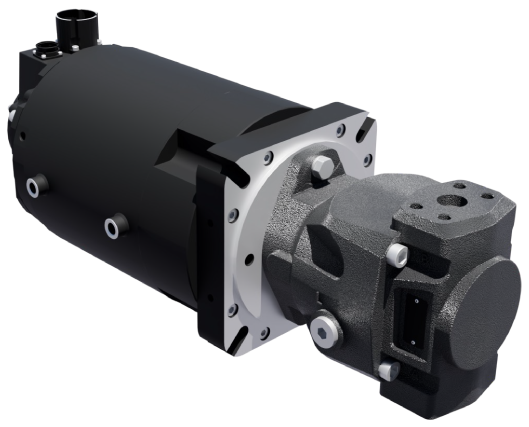

Drive Train Motor

Drive Train Motor

Electric motor and Final Drive assembly for wheeled vehicles.

Advantages

Ability to modify standard series to meet performance requirements

Increased productivity and improved cycle times

Improved product quality through accurate control

Stator

3 Phase Power Connection

Coolant Ports

Drive Train Motor

Pump Drive Motor

Pump drive motors convert electrical energy into mechanical energy that then drives a hydraulic pump. The servo motor receives 3-phase power from the inverter to provide immediate and efficient power to the hydraulic pump, unlike a diesel engine.

Advantages

Flexible configurations with ability to modify standard series to meet performance requirements

Integrated load holding brakes provide load holding capabilities

Thermistor monitors internal motor temperature and liquid cooling prevents overheating

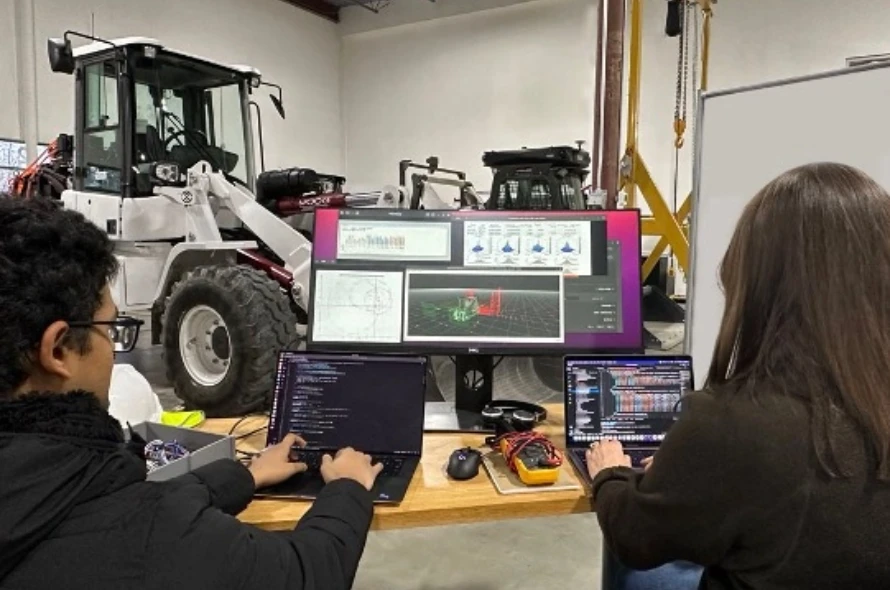

Software Development Environment

Software Support and Co-Creation of Application

Advantages

Remote diagnostics enabled with interfaces to cloud database and onboard analytics for decision making

Built-in algorithms and a developer toolbox enable you to build in your machine differentiation with more software-enabled functionality for greater productivity and tool usage

Ready for digital connectivity, continuous learning, and your next level of automation

Partner with us for

greater sustainability,

productivity, and a digitally

connected future.